Our range of services

The production of acoustically effective components is characterized by a variety of different manufacturing processes and process steps.

The RAT team of specialists has a profound knowledge of these processes. Our team projects, constructs and produces the tools for all manufacturing processes adapted to the respective needs and requirements.

For us, it is also a matter of course to support our customers during the product development already. Together with you, we identify optimization potential and cost saving possibilities at an early stage.

Due to our modern machine park, we have a high vertical range of manufacture and are in a position to realize short processing times as possible.

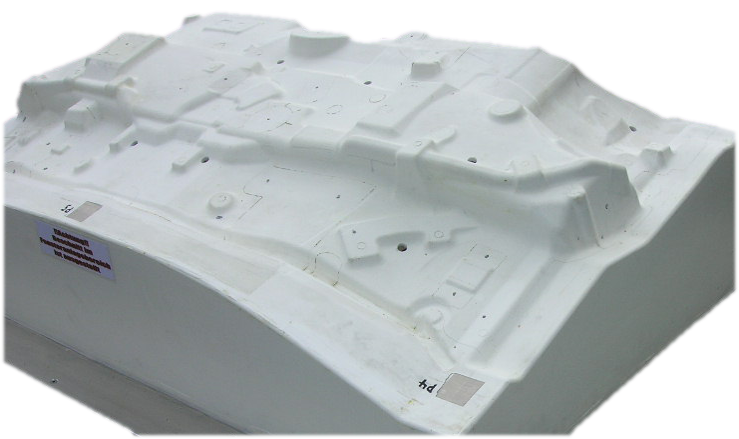

Our in house model construction allows us to supply you with the corresponding tool concepts during the production phase of the prototype or preproduction run already.

By means of various measuring methods we ensure the quality of our products.

In addition, we provide the opportunity of digitalisation and surface reconstuction.

Our portfolio is rounded out with a comprehensive range of services. In this way, we assist you from the initial operation up to the serial cycle of the tools in your company. We also support you in respect of the maintenance and care of the tools we produce. All modifications of the tools are implemented at short notice and in due time.

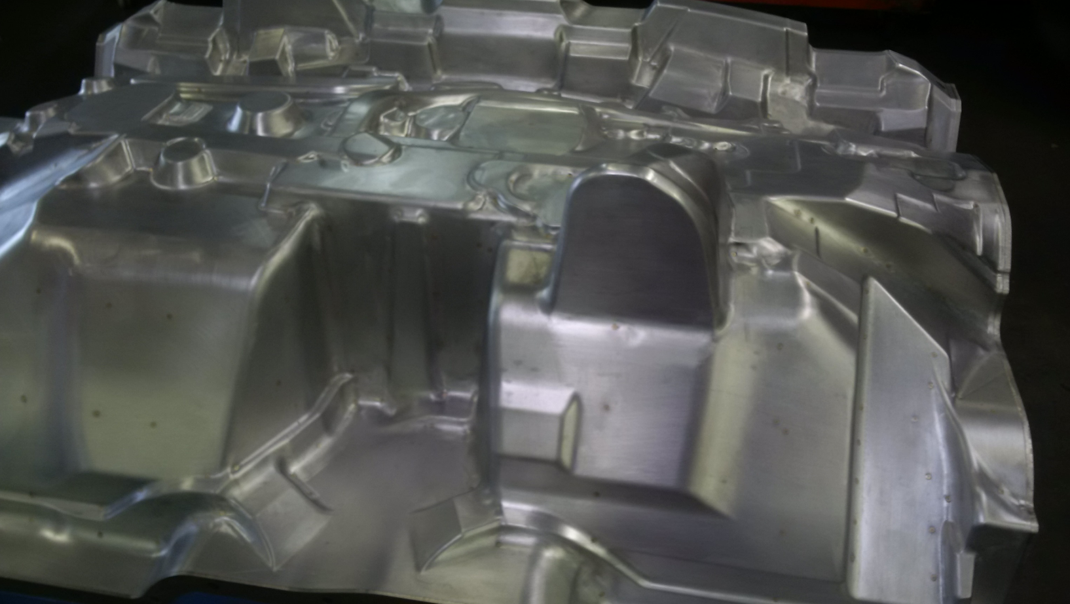

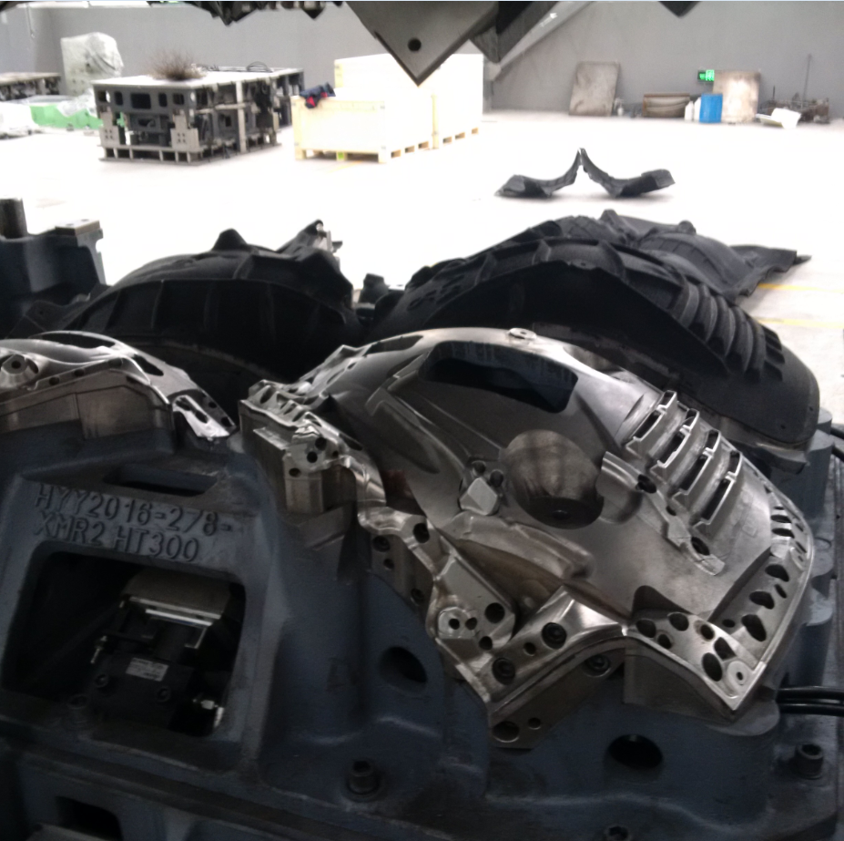

Forming tools

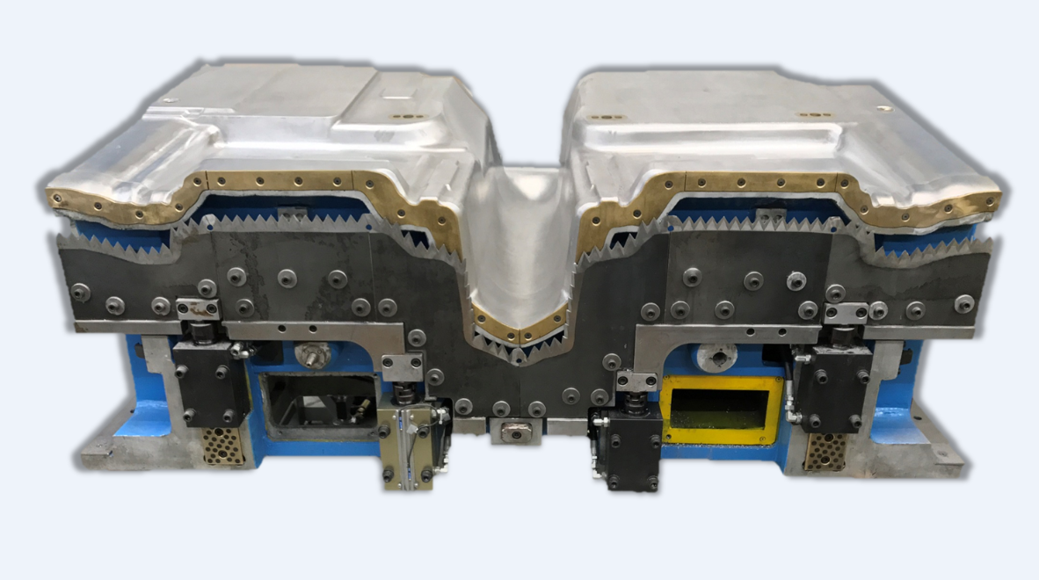

Pressing tools

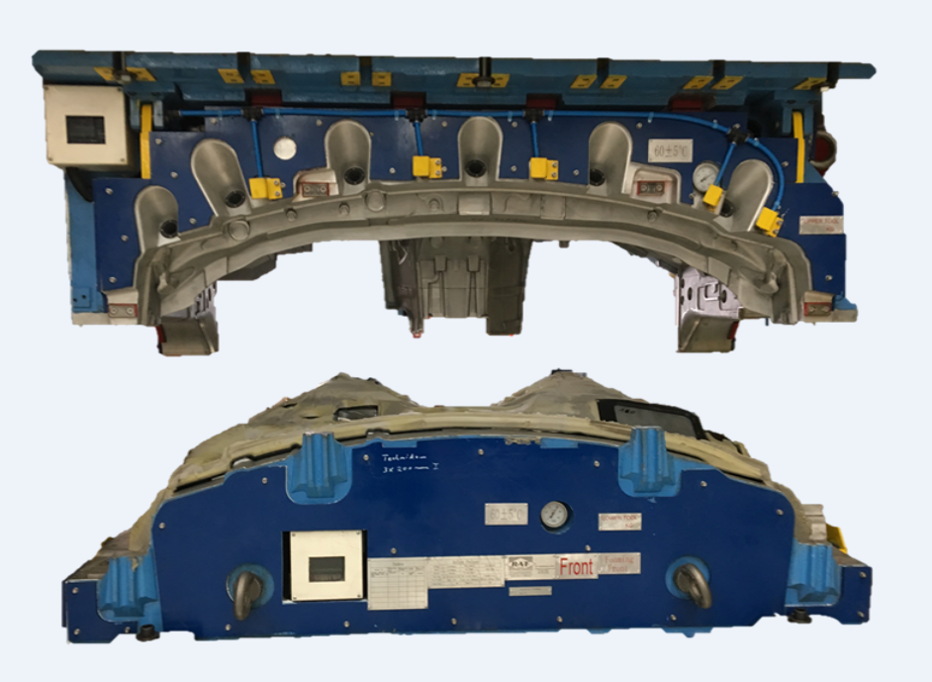

Thermoforming tools

Tools for the manufacturing of fiber components

Press pinch tools

Image follows.

Foaming tools

Separation uptake (waterjet and laser)

Punching tools

Punching devices

Testing instruments

Aids and handling devices

Image follows.

Mounting devices

Machine data

| 5-axis CNC milling | X 4000 ; Y 2000 ; Z 1500 |

|---|---|

| CNC boring mill | X 2200 ; Y 2000 ; Z 1500 |

| Turning | X 1000; Y 200 |

| Spotting press: | bis 35t Formgewicht |

| 3D-scaling | |

| Digitalization |